噴塑生產(chǎn)線的烤箱工作原理

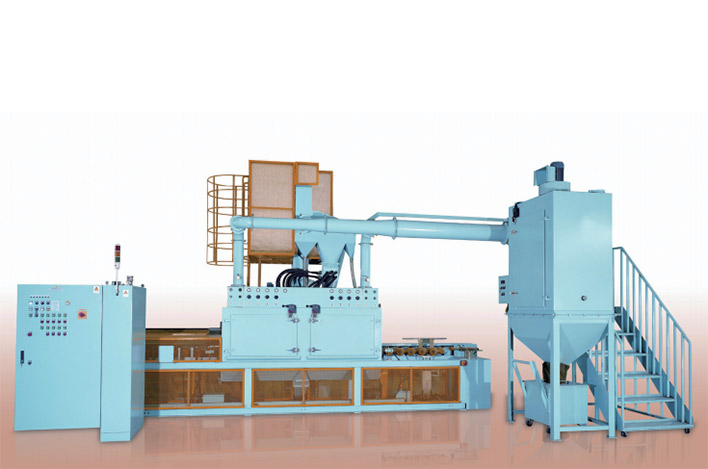

噴塑生產(chǎn)線中的烤箱(也稱為固化爐或烘箱)是用于將噴涂在工件表面的粉末涂料加熱并熔化,使其流平、固化,形成一層堅硬、耐用且美觀的涂層。以下是噴塑生產(chǎn)線中烤箱的工作原理及其相關過程:

The oven (also known as a curing oven or oven) in the spray coating production line is used to heat and melt the powder coating sprayed on the surface of the workpiece, making it level and solidify, forming a hard, durable, and beautiful coating. The following is the working principle and related process of the oven in the spray coating production line:

1. 粉末噴涂

1. Powder coating

預處理:在進入烤箱之前,工件需要經(jīng)過表面預處理,包括脫脂、磷化、水洗等步驟,以確保工件表面干凈、無油污和銹跡,提高涂層的附著力。

Pre treatment: Before entering the oven, the workpiece needs to undergo surface pre-treatment, including degreasing, phosphating, water washing, etc., to ensure that the surface of the workpiece is clean, free of oil stains and rust, and to improve the adhesion of the coating.

靜電噴涂:使用靜電噴槍將帶電的粉末顆粒噴涂到接地的工件上,由于靜電作用,粉末會均勻地吸附在工件表面。

Electrostatic spraying: Use an electrostatic spray gun to spray charged powder particles onto a grounded workpiece. Due to the electrostatic effect, the powder will be evenly adsorbed on the surface of the workpiece.

2. 進入烤箱

2. Enter the oven

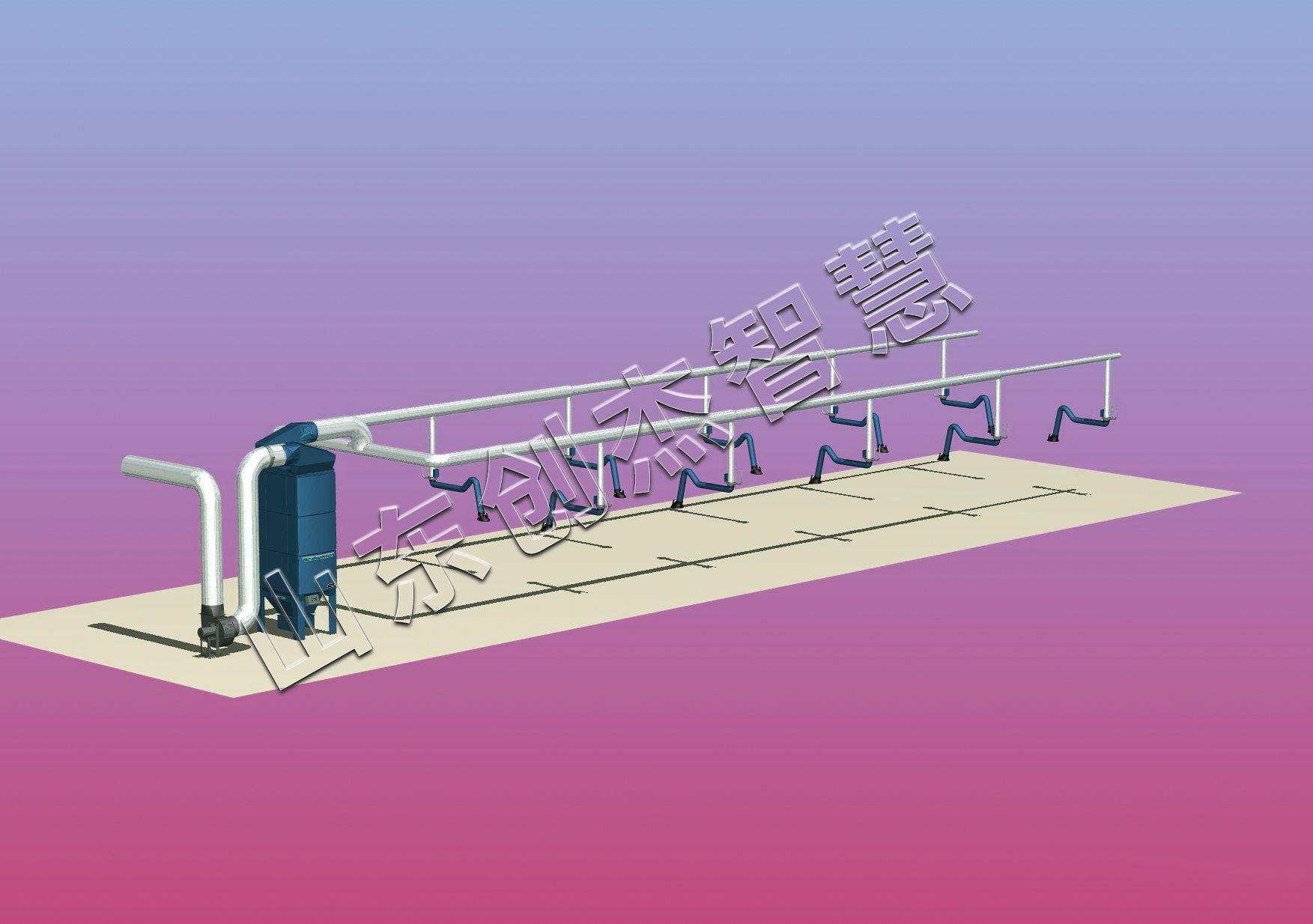

裝載:噴涂完畢的工件通過輸送鏈或其他傳輸設備送入烤箱內(nèi)。

Loading: The sprayed workpiece is sent into the oven through a conveyor chain or other conveying equipment.

溫度控制:烤箱內(nèi)部設有溫度控制系統(tǒng),能夠根據(jù)不同的粉末類型和工件材質(zhì)設定合適的加熱溫度,通常范圍為180°C至250°C之間。

Temperature control: The oven is equipped with a temperature control system that can set the appropriate heating temperature according to different powder types and workpiece materials, typically ranging from 180 ° C to 250 ° C.

3. 加熱與熔化

3. Heating and melting

傳導加熱:烤箱內(nèi)的熱源可以是電加熱管、燃氣燃燒器或紅外線加熱器等,它們產(chǎn)生的熱量通過輻射、對流和傳導的方式傳遞給工件。

Conductive heating: The heat source inside the oven can be electric heating tubes, gas burners, or infrared heaters, etc. The heat generated by them is transferred to the workpiece through radiation, convection, and conduction.

粉末熔化:隨著溫度升高,吸附在工件表面的粉末逐漸軟化、熔融,并開始流動,填平表面的微小凹凸不平之處,形成光滑的液態(tài)層。

Powder melting: As the temperature increases, the powder adsorbed on the surface of the workpiece gradually softens, melts, and begins to flow, filling in the small unevenness of the surface and forming a smooth liquid layer.

4. 流平與固化

4. Leveling and solidification

流平:在一定時間內(nèi),熔化的粉末會在重力和表面張力的作用下自然流平,消除氣泡和瑕疵,形成均勻的涂層。

Leveling: Within a certain period of time, the melted powder will naturally level under the action of gravity and surface tension, eliminating bubbles and defects, and forming a uniform coating.

化學交聯(lián):當溫度達到粉末的固化點時,粉末中的樹脂成分會發(fā)生化學反應,即交聯(lián)反應,使得涂層從液態(tài)轉變?yōu)楣虘B(tài),形成堅固的保護膜。

Chemical crosslinking: When the temperature reaches the solidification point of the powder, the resin components in the powder undergo a chemical reaction, known as crosslinking reaction, causing the coating to transform from liquid to solid, forming a strong protective film.

5. 冷卻

5. Cooling

自然冷卻:工件在完成固化后,隨著輸送系統(tǒng)離開烤箱,進入冷卻區(qū)域。在這個過程中,涂層逐漸降溫并完全硬化。

Natural cooling: After the workpiece is cured, it leaves the oven with the conveyor system and enters the cooling area. During this process, the coating gradually cools down and fully hardens.

強制冷卻(可選):對于某些要求快速生產(chǎn)周轉的應用,可以在烤箱出口處設置冷卻裝置,如風扇、水簾等,加速工件的冷卻速度,縮短生產(chǎn)周期。

Forced cooling (optional): For certain applications that require rapid production turnover, cooling devices such as fans, water curtains, etc. can be installed at the oven outlet to accelerate the cooling speed of the workpiece and shorten the production cycle.

6. 質(zhì)量檢查

6. Quality inspection

外觀檢驗:冷卻后的工件應進行外觀質(zhì)量檢查,確保涂層厚度均勻、顏色一致、無缺陷(如針孔、氣泡、裂紋等)。

Appearance inspection: After cooling, the workpiece should undergo appearance quality inspection to ensure uniform coating thickness, consistent color, and no defects (such as pinholes, bubbles, cracks, etc.).

性能測試:根據(jù)具體需求,可能還需要對涂層的硬度、附著力、耐腐蝕性等物理化學性能進行測試。

Performance testing: Depending on specific requirements, physical and chemical properties such as hardness, adhesion, and corrosion resistance of the coating may also need to be tested.

7. 安全與環(huán)保

7. Safety and Environmental Protection

廢氣處理:烤箱運行過程中可能會產(chǎn)生少量揮發(fā)性有機化合物(VOCs),因此需要配備有效的廢氣處理系統(tǒng),如活性炭吸附、催化燃燒等,以減少對環(huán)境的影響。

Exhaust gas treatment: During the operation of the oven, a small amount of volatile organic compounds (VOCs) may be generated, so an effective exhaust gas treatment system such as activated carbon adsorption, catalytic combustion, etc. is needed to reduce the impact on the environment.

操作安全:烤箱的操作人員必須遵守嚴格的安全規(guī)程,佩戴適當?shù)膫€人防護裝備,防止燙傷、火災等事故發(fā)生。

Operation safety: Oven operators must comply with strict safety regulations, wear appropriate personal protective equipment, and prevent accidents such as burns and fires.

8. 溫度曲線優(yōu)化

8. Temperature curve optimization

溫度曲線監(jiān)測:為了保證最佳的涂裝效果,現(xiàn)代噴塑生產(chǎn)線通常配備有溫度曲線記錄儀,它可以實時監(jiān)控每個工件在整個加熱過程中的溫度變化,幫助調(diào)整和優(yōu)化烤箱的工作參數(shù)。

Temperature curve monitoring: In order to ensure the best coating effect, modern spray coating production lines are usually equipped with temperature curve recorders, which can monitor the temperature changes of each workpiece in real time throughout the heating process, helping to adjust and optimize the working parameters of the oven.

節(jié)能措施:通過合理設計烤箱的保溫結構、采用高效的加熱元件以及實施智能溫控策略,可以有效降低能耗,提高能源利用效率。

Energy saving measures: By designing the insulation structure of the oven reasonably, using efficient heating elements, and implementing intelligent temperature control strategies, energy consumption can be effectively reduced and energy utilization efficiency can be improved.

9. 特殊應用

9. Special applications

分段式烤箱:對于大型或復雜形狀的工件,可以使用分段式烤箱,即將整個加熱過程分為預熱、主加熱和保溫等多個階段,每個階段設置不同的溫度和時間,以適應不同部位的加熱需求。

Segmented oven: For large or complex shaped workpieces, a segmented oven can be used, which divides the entire heating process into multiple stages such as preheating, main heating, and insulation. Different temperatures and times are set for each stage to meet the heating needs of different parts.

多用途烤箱:一些先進的烤箱不僅可以用于粉末涂料的固化,還可以兼容其他類型的涂裝工藝,如液體油漆的烘干、金屬件的熱處理等,提高了設備的利用率。

Multi purpose ovens: Some advanced ovens can not only be used for curing powder coatings, but also compatible with other types of coating processes, such as drying liquid paints, heat treatment of metal parts, etc., improving equipment utilization.

綜上所述,噴塑生產(chǎn)線中的烤箱通過精確的溫度控制和合理的加熱方式,實現(xiàn)了粉末涂料的熔化、流平和固化,形成了優(yōu)質(zhì)的涂層。正確配置和維護烤箱對于確保產(chǎn)品質(zhì)量、提高生產(chǎn)效率以及保障環(huán)境友好至關重要。

In summary, the oven in the spray coating production line achieves the melting, leveling, and solidification of powder coatings through precise temperature control and reasonable heating methods, forming high-quality coatings. Proper configuration and maintenance of ovens are crucial for ensuring product quality, improving production efficiency, and ensuring environmental friendliness.

本文由 噴塑生產(chǎn)線 友情奉獻.更多有關的知識請點擊 http://m.gtjjw.cn 真誠的態(tài)度.為您提供為全面的服務.更多有關的知識我們將會陸續(xù)向大家奉獻.敬請期待.

This article is a friendly contribution from the spray coating production line For more related knowledge, please click http://m.gtjjw.cn Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

上一篇:電泳線是哪里導電

下一篇:焊煙除塵設備使用規(guī)范

魯公網(wǎng)安備 37142502000144號

魯公網(wǎng)安備 37142502000144號