多工位焊接煙塵凈化系統的使用

(1)焊接煙塵的治理設備 金屬焊接產生的懸浮在空氣中的顆粒非常小,是“可呼吸”的,并稱其為焊接煙霧。這種焊接煙霧中含有氣態和顆粒狀態對人體有害的污染物質。治理的目的:一是使室內有害污染物的濃度小于國家強制性標準和《工作場所有害因素職業接觸界限值》所規定的車間空氣中焊接煙塵衛生標準(電焊煙塵醉高允許濃度為6mg/m3,鋁合金焊接煙塵為4mg/m3?);二是排向大氣的污染物濃度達到國家環保要求。?由于焊煙的塵埃粒徑微小,一般的過濾材質無法過濾焊接煙塵,應采用聚四氟乙烯覆膜濾筒式過濾器,采用集中式整體煙塵處理設備,脈沖反吹清灰,確保過濾精度。

(1) The treatment equipment for welding smoke and dust produces very small particles suspended in the air during metal welding, which are "breathable" and are called welding smoke. This welding smoke contains pollutants in both gaseous and particulate states that are harmful to human health. The purpose of governance is to make the concentration of indoor harmful pollutants lower than the national mandatory standards and the hygiene standards for welding smoke and dust in the workshop air specified in the Occupational Exposure Limits for Hazardous Factors in the Workplace (the allowable concentration of welding smoke and dust is 6mg/m3, and the allowable concentration of aluminum alloy welding smoke and dust is 4mg/m3); The second is that the concentration of pollutants discharged into the atmosphere meets national environmental protection requirements.? Due to the small particle size of welding smoke, ordinary filtering materials cannot filter welding smoke. Therefore, polytetrafluoroethylene membrane filter cartridge type filters should be used, and centralized overall smoke and dust treatment equipment should be used. Pulse back blowing is used to clean the dust, ensuring filtration accuracy.

(2)高效覆膜聚酯濾筒的性能特點 聚四氟乙烯(PTFE)覆膜聚酯濾材是一種高科技產品,它的微孔結構可在特殊條件下經機械拉伸得到,而絲毫未改變其原有特性。微孔過濾覆膜孔徑可控制在0.2~0.3mm,過濾方法屬于膜表面過濾。膜表面光滑又具備極佳的化學穩定性,能抗腐蝕,耐酸堿。不老化又憎水性。在過濾時膜表面截留的粉塵很容易剝落,其通氣量能長時期保持在同一水平上。由于覆膜濾材是用其光滑不粘的表面截留粉塵,利用這一特性即可節約脈沖清灰系統的壓縮空氣量,又可避免煙塵對薄膜基布的磨損,延長了濾筒的使用壽命。同時為設備提供醉低而平穩的壓降差。

(2) The performance characteristics of high-efficiency coated polyester filter cartridges are polytetrafluoroethylene (PTFE) coated polyester filter materials, which are high-tech products. Its microporous structure can be obtained through mechanical stretching under special conditions without changing its original characteristics. The pore size of the microporous filtration membrane can be controlled between 0.2-0.3mm, and the filtration method belongs to membrane surface filtration. The surface of the membrane is smooth and has excellent chemical stability, which can resist corrosion and acid and alkali. Not aging and hydrophobic. The dust trapped on the membrane surface during filtration is easily peeled off, and its ventilation capacity can be maintained at the same level for a long time. Due to the use of its smooth and non stick surface to retain dust, the use of this feature can save the compressed air volume of the pulse cleaning system and avoid the wear of the film substrate by smoke and dust, thereby extending the service life of the filter cartridge. Simultaneously providing equipment with a low and stable pressure drop difference.

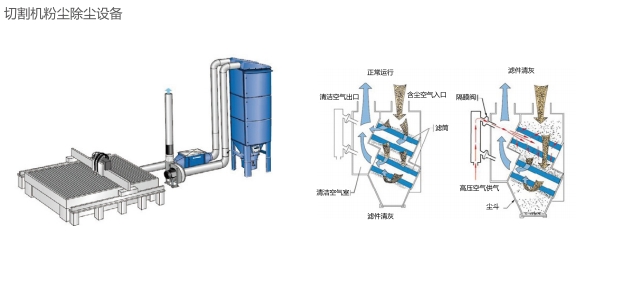

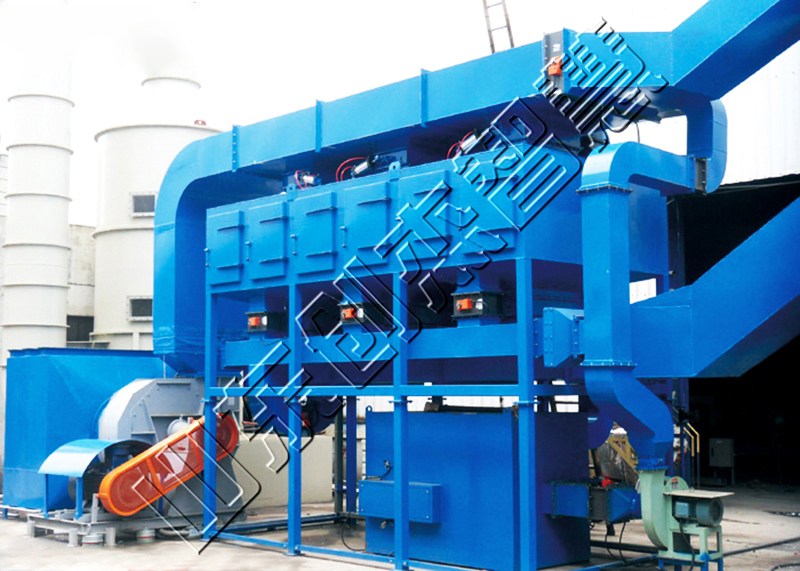

車間焊煙技術除塵煙塵凈化系統又被稱為多工位焊接煙塵凈化系統。主要由過濾單元(除塵器)、大風量吸塵風機、排風管道、電控系統、系統相關配件及操作主件組成。主要是針對焊接工位較多且緊湊、同時加工多種工序及工況較復雜的車間環境治理。主過濾單元所選用的除塵器型號主要根據多工位焊煙凈化系統的具體要求來決定,具體要求包括排風管道的管徑、長度尺寸;具體的操作工位數量以及需處理面積的排風風量;所處理的煙塵材料的物理及化學性能以及主過濾器、管道、電控,乃至整個除塵系統所處的環境等諸多因素。中央焊接煙塵凈化系統流程說明:根據不同的工況為焊接工位設計不同的收集裝置,從污染源頭經收集裝置進入主排風管道,這個過程會將煙氣粉塵瞬間收集,保證了工作人員自身健康問題;而后經主管道進入過濾單元(除塵器),煙塵被除塵器中的濾材高度凈化,煙氣粉塵會在風機負壓的作用在附著在濾材表面,脈沖閥控制濾材的自動清灰功能,在脈沖閥及控制程序的作用下,系統會每隔一段時間對濾材從內而外進行反吹清灰,沉流式的設計原理保證反吹過程中的顆粒物及細微粉塵落入集灰桶集中收集,收集后的顆粒粉塵需根據使用周期及煙塵量的大小定期外運清理,凈化后的達標氣體在風機的作用下經煙筒外排。

The workshop welding smoke technology dust removal and purification system is also known as the multi station welding smoke purification system. It mainly consists of a filtering unit (dust collector), a high air volume vacuum fan, exhaust pipes, an electrical control system, system related accessories, and operating main components. Mainly aimed at workshop environment management with multiple and compact welding workstations, simultaneous processing of multiple processes, and complex working conditions. The model of dust collector selected for the main filtration unit is mainly determined based on the specific requirements of the multi station welding smoke purification system, including the diameter and length size of the exhaust duct; The specific number of operation stations and the exhaust air volume of the area to be processed; The physical and chemical properties of the processed smoke and dust materials, as well as various factors such as the main filter, pipelines, electrical control, and even the environment in which the entire dust removal system is located. Process description of the central welding smoke and dust purification system: Different collection devices are designed for the welding station according to different working conditions. From the source of pollution, the collection device enters the main exhaust duct. This process will instantly collect the smoke and dust, ensuring the health of the workers themselves; Then, it enters the filtering unit (dust collector) through the main pipeline, and the smoke and dust are highly purified by the filter material in the dust collector. The smoke and dust will adhere to the surface of the filter material under the negative pressure of the fan. The pulse valve controls the automatic cleaning function of the filter material. Under the action of the pulse valve and control program, the system will periodically blow back the filter material from the inside out for cleaning. The design principle of the settling flow ensures that particles and fine dust during the back blowing process fall into the ash collection bucket for centralized collection. The collected particle dust needs to be regularly transported and cleaned according to the service cycle and the size of the smoke and dust. The purified standard gas is discharged through the chimney under the action of the fan.

焊接車間濾筒除塵器對焊接煙塵治理為焊接工位(補焊工位)—集塵罩—阻火器—電動調風閥—分支管路—主管路—濾筒除塵器—風機—高空排放。

The welding workshop filter cartridge dust collector controls welding smoke and dust by welding station (welding repair station) - dust collection hood - flame arrester - electric air regulating valve - branch pipeline - main pipeline - filter cartridge dust collector - fan - high-altitude discharge.

本文由多工位焊煙除塵設備友情奉獻.更多有關的知識請點擊:http://m.gtjjw.cn真誠的態度.為您提供為全面的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from the multi station welding smoke and dust removal equipment. For more related knowledge, please click: http://m.gtjjw.cn Sincere attitude. We will provide you with comprehensive service. We will gradually contribute more relevant knowledge to everyone. Stay tuned

上一篇:機器人涂裝線的產品特點和技術參數

下一篇:涂裝行業廢氣治理:沸石轉輪催化燃燒設備

魯公網安備 37142502000144號

魯公網安備 37142502000144號